Plasma Nitriding Systems

Of all available nitriding processes, plasma nitriding provides the most consistent results and the highest level of reliability. Why? Because plasma nitriding systems use precisely controlled technology that ensures dependable quality.

Organizations looking for plasma nitriding systems have various options. At Electron, we offer IonHeat GlowTech, NitrEos, and GlowFit systems. Each system has its own unique properties. Read on to find out more about the various plasma nitriding solutions and their benefits.

Hardness and resistance

Stainless steel, particularly the austenitic stainless grades, is widely used in industry due to their corrosion resistance. The downside of these materials? They possess very poor mechanical properties – low surface hardness and wear resistance limit their usability. Plasma nitriding is one of the few effective ways to increase the surface hardness of stainless steel.

Plasma nitriding is an environmentally friendly and efficient nitriding process that uses plasma as energy source of gas nitriding species, cleaning power and energy to raise the temperature of the parts. It allows for a new level of precision and control, which results in uniform and consistent case hardening without the side effects (the release of polluting chemicals, high gas consumption) of other nitriding technologies.

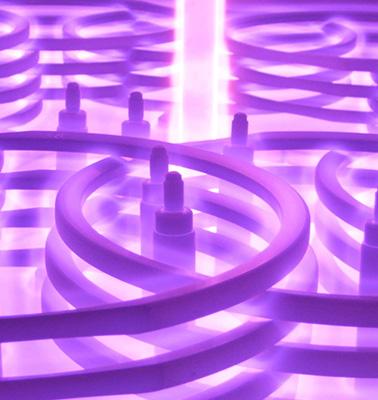

Plasma ion nitriding technology

Ion/plasma nitriding processes are carried out in a vacuum vessel where a high-voltage electrical charge forms plasma. This process allows nitrogen ions to accelerate. As a result of this acceleration, the ions cling to the metal, heating it up, cleaning the surface, and allowing the metal to absorb nitrogen and carbon (in the case of plasma nitrocarburizing). This makes the surface of the metal more resilient to corrosion, erosion and galling.

At Electron, we don’t only have the products to help you use plasma nitriding technology in the best way, but we also specialize in co-engineering ion/plasma nitriding solutions with our customers. Thanks to years of experience in supplying the equipment and process knowledge, Electron can provide turnkey solutions or carry out a fast and efficient co-engineering process to get the best out of modern plasma ion nitriding technology.

High-tech plasma nitriding furnaces for optimal surface hardness and excellent resistance

Electron - Experts in Thermal Process Installations & Material Handling

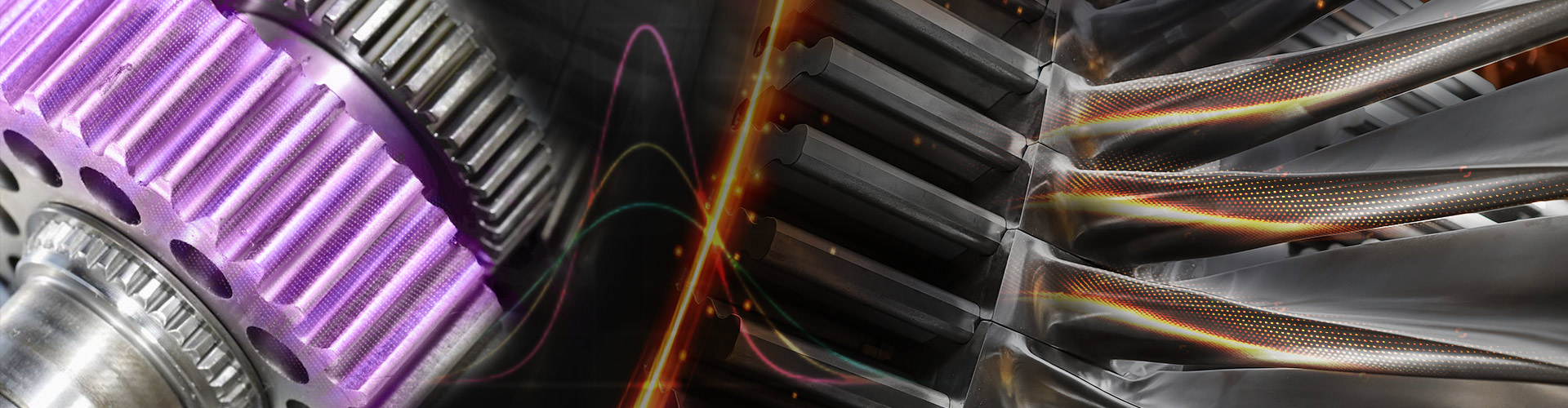

Ion/plasma nitriding applications

Plasma nitriding has become a popular technology in the industrial community. Applications include gears, crankshafts, camshafts, cam followers, valve parts, extruder screws, pressure-die-casting tools, forging dies, cold forming tools, injectors and plastic-mold tools, long shafts, and axis, clutch and engine parts. Plasma nitriding technology is also used in the aerospace industry to improve the reliability and durability of commonly used materials such as Aluminum, stainless steel, Titanium and Nitralloys and Nickel alloys.

What ion/plasma nitriding technology ultimately does is case-hardening. It hardens the surface of a metal object while allowing the metal deeper underneath to remain soft, thus forming a thin layer of harder metal at the surface. The process makes hardened metal more resistant to surface wear. Ideal for objects that are subject to sliding contact with hard or abrasive materials.

Our plasma nitriding systems and furnaces

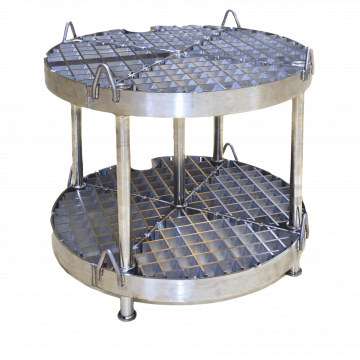

IonHeat GlowTech

IonHeat GlowTech is a modular system that allows you to assemble the furnace according to your business needs. The system is NADCAP compliant. With advanced automation features, our GlowTech systems reach new heights in ion/plasma nitriding processes. The most important benefits of GlowTech system are:

- Modular expansion of capabilities for a lean system and minimal start-up costs

- Easy production volume scale up from single to semi-tandem to full tandem plasma nitriding systems for minimal reinvesting costs and an optimal production and business ROI.

GlowTech offers the widest and most advanced range of options and guarantees perfectly controlled metallurgical results.

IonHeat NitrEos

IonHeat NitrEos is a compact furnace system for standardized processes and repeatability of results. NitrEos is an all-new innovative lightweight single furnace design and a turnkey solution.

NitrEos is an excellent choice if you’re looking for consistent results with fixed product volumes. It’s a tried and trusted cost-effective system for quick and reliable plasma nitriding processes.

Installation and commissioning of the NitrEos system is fast and easy.

IonHeat GlowFit units

You could describe the IonHeat GlowFit unit as a new heart to modernize your old furnace. The “old school” ion nitriding systems from the twentieth century still have the capacity to nitride your parts like champs! But why would you want to convert an existing furnace?

Efficiency gain and cost savings are two excellent reasons, especially in a time in which energy bills are going through the roof.

Installing our retrofitting kit will allow you to upgrade existing plants with new controls, gas panels, top-of-the-line plasma power supplies, and our unique SCADA man/machine software. GlowFit units can be used for existing cold-wall or hot-wall units.

Advanced ion/plasma nitriding process engineering

To carry out ion/plasma processes properly, you need more than just the right tools and products. Knowledge and process engineering are also important parts of the equation. The good news? Electron doesn’t only offer the right ion and plasma nitriding systems; we also excel at process technology.

That means that we give you the recipes for the successful utilization of plasma nitriding systems. Additionally, we are also able to assist you with consulting services and the implementation of plasma nitriding technology.

Nitriding and carbo-nitriding at a low temperature, at a lower cost and with fewer emissions.