Custom tube furnaces: high-temperature solutions for research & industry

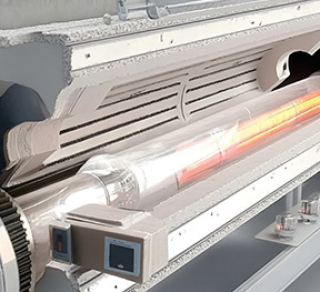

Ultra-high temperature tube furnaces

Ultra-high temperature furnaces for SiC wafer processing. UHT tube furnaces up to 2200°C. Our hot-wall furnace design ensures optimal performance.

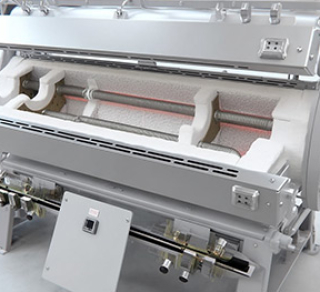

Custom split tube furnaces: precision-engineered thermal solutions

Electron's custom split tube furnaces deliver exceptional thermal uniformity. Engineered for research, OEMs and industrial processing for reliable results.

Custom rotary tube furnaces: high-temperature material processing systems

Electron's custom rotary tube furnaces deliver continuous rotation for uniform heating. Engineered for research, OEMs and industrial processing for reliable results.

Custom laboratory tube furnaces: precision research solutions

Electron's custom lab tube furnaces deliver research-grade precision with tailored configurations, advanced control, and specialized atmospheres.

Custom high-performance tube furnaces: engineered for research & industry

Our process-first approach delivers precision-engineered thermal solutions, from ultra-high temperature (UHT) and split tube furnaces to rotary and laboratory systems. Electron's custom tube furnace designs range from 1100°C to 2200°C, combining flexible temperature zones with REACH-compliant materials. These tailored systems support applications from compact analytical instruments to large-scale industrial processes with integrated reactor designs up to 400cm.

Custom tube furnaces for OEM analysis equipment

Analytical instrument manufacturers rely on Electron's compact heating elements and tube furnaces for seamless system integration. Engineered for exceptional temperature stability and proven longevity, these custom solutions maintain competitive advantages in analytical precision while meeting strict space and performance requirements.

Tube furnaces for R&D and scientific applications

Technical universities and R&D centers advance breakthrough research in catalysis, fuel development, and chemical process optimization with Electron's precision high-temp tube furnaces. Multiple heating zones and exact temperature control support critical investigations in carbon capture, novel materials development, and process innovation.

Custom tube furnace systems for industrial processing

Production environments demand maximum uptime and efficiency. Electron's industrial high-temperature tube furnaces deliver complete turnkey thermal processing systems featuring robust frames with integrated controls, and optimized gas flow management. The process-first approach ensures optimal performance while minimizing energy consumption and maintenance requirements.

Features & specifications of Electron’s tube furnaces

Advanced features

- Premium Kanthal heating elements

- Multiple independent heating zones

- Energy-efficient thermal insulation

- Tailormade tube furnaces with customizable configurations

- High-precision temperature control

- Modular design

Key technical specifications

- Temperature range: 1100°C - 2200°C

- Furnace diameters: 10mm - 200mm

- Heated lengths: 200mm - 2000mm

- Process tube materials: Ceramic, Quartz Glass, Silicon Carbide, Metal

- Multiple heating zone configurations

- Horizontal or vertical orientation options

Electron's heating modules consistently deliver the precise temperature control our analytical instruments require for reliable results.

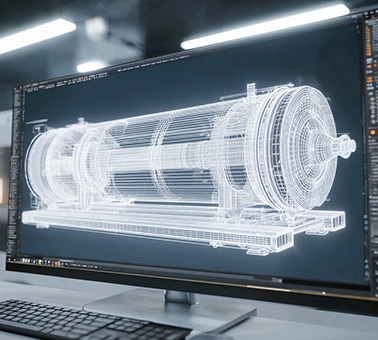

Expert guidance for custom high temperature tube furnaces

Creating the optimal thermal processing solution requires deep application knowledge and engineering expertise. Electron's thermal specialists analyze specific process requirements to develop custom tube furnace configurations that deliver optimal results.