Custom rotary tube furnaces: high-temperature material processing systems

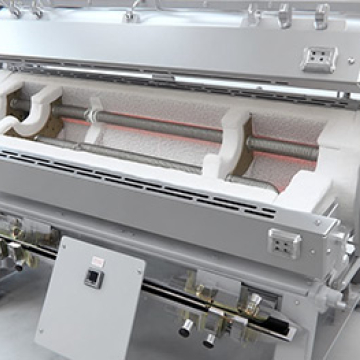

Electron's advanced rotary tube furnaces deliver exceptional thermal performance and material processing capabilities for demanding high-temperature applications. These custom-built systems feature continuous rotation for uniform heating, adaptable reactor materials, and customizable configurations to match exact process requirements. With operating temperatures extending to 1700°C, these robust systems ensure consistent, reliable performance.

Electron’s engineering team delivers fully customized furnace solutions that push the boundaries of temperature control and thermal efficiency.

Custom rotary tube furnaces for advanced thermal processing

At Electron, every rotary tube furnace is engineered to meet a specific process challenge—whether for material development laboratories or high-throughput production. Our process-first approach supports complex physicochemical processes, specialized reactor materials, and custom mounting options for maximum compatibility.

The purpose-built systems ensure energy-efficient performance, consistent results, and long-term reliability, giving thermal processing specialists the precision and uniform material exposure required to operate at the highest standards.

Custom rotary tube furnaces for advanced thermal processing

At Electron, every rotary tube furnace is engineered to meet a specific process challenge—whether for material development laboratories or high-throughput production. Our process-first approach supports complex physicochemical processes, specialized reactor materials, and custom mounting options for maximum compatibility.

The purpose-built systems ensure energy-efficient performance, consistent results, and long-term reliability, giving thermal processing specialists the precision and uniform material exposure required to operate at the highest standards.

Need help selecting the right rotary tube furnace?

Not sure which rotary tube furnace configuration matches specific process requirements? Electron's thermal engineers provide expert guidance for optimal system design and integration.

Key features

Each Electron rotary tube furnace is a tailor-made thermal system, designed around a specific process—not a catalogue of fixed specs..

- Rotating tube design for uniform material heating and mixing

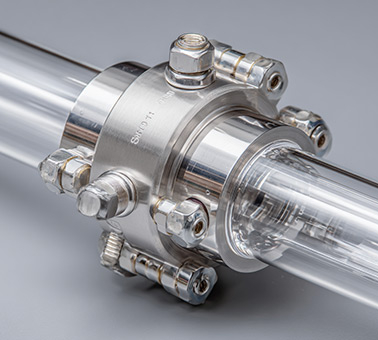

- Multiple reactor material options: quartz, ceramic, metal, or glass

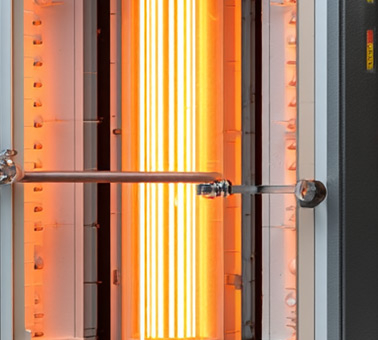

- Advanced temperature control systems for precise thermal profiles

- Complete in-house design and manufacturing capabilities

- Continuous or batch processing capabilities

- Gas flow optimization for reactive processes

- Customized for operation to 1700°C depending on application requirements

Customization for specialized applications

Electron's rotary tube furnaces adapt to the most challenging process requirements. From specialized material development to coating applications, each system is designed around specific thermal profiles, rotation parameters, and integration needs.

Common customizations include specialized atmosphere control systems, additional temperature monitoring points, adjustable rotation speeds, and custom reactor configurations—all engineered to maintain optimal performance while addressing unique operational challenges.

Electron's engineering team provides comprehensive thermal process analysis, identifying critical parameters and designing custom furnace solutions that optimize both technical performance and operational efficiency for specialized applications.

High-performance rotary tube furnaces for advanced applications

Electron delivers exceptional uniformity and continuous material processing for research laboratories, materials developers, and industrial manufacturing operations. Each system offers unparalleled durability with adaptable configurations for specialized thermal processes up to 1700°C.

Why choose Electron?

With a proven track record of delivering high-performance furnaces, Electron offers rotary tube furnace solutions tailored to the most demanding material processing applications. Our expertise in precision heating, advanced customization, and seamless integration ensures exceptional performance, reliability, and efficiency for every project.

In-depth process expertise and strategic partnership

Electron isn’t just a supplier, we are your strategic partner. Our in-house R&D facilities and process validation capabilities empower us to offer unique insights and solutions. We understand the challenges of scaling from laboratory setups to full-scale production, guiding you through every technical and strategic decision to optimize your process performance.

Custom-designed systems for precision and efficiency

No two processes are identical. That’s why Electron specializes in fully tailored rotary furnace solutions for diverse applications: from material development to surface treatment to laboratory research. We design bespoke systems that integrate seamlessly into existing setup, ensuring that every configuration meets unique operational needs.

Expert support and guidance throughout the process

Choosing Electron means gaining a dedicated team of engineers and thermal processing specialists who provide comprehensive support from initial consultation through installation, testing, and optimization. Our expertise ensures efficient scale-up, improved process control, and superior results, making our customers’ success our top priority.

Applications of custom rotary tube furnaces

Rotary tube furnaces from Electron support critical thermal processes across multiple industries, with custom configurations available for specialized applications.

Material development & processing

Research and production facilities rely on Electron's rotary tube furnaces for precise material transformation processes.

The continuous rotation ensures uniform thermal exposure essential for sintering advanced ceramics, pyrolyzing carbon-based materials, and calcining specialized powders.

Multi-zone configurations maintain exact temperature profiles, while specialized reactor materials accommodate corrosive environments and ultra-high temperature requirements up to 1700°C and beyond.

Coating & surface treatment

Manufacturing operations leverage Electron's rotary systems for uniform coating deposition and surface modification.

These precision-engineered furnaces support critical processes including chemical vapor deposition, diffusion coating, and thermal spray preparation with exceptional consistency.

The rotational design ensures complete coverage while maintaining precise temperature and atmospheric conditions, delivering superior coating quality for metals, ceramics, and composite materials.

Laboratory research & analysis

Advanced research laboratories utilize Electron's compact rotary tube furnaces for controlled atmosphere testing and thermal analysis.

These systems feature specialized reactor configurations for oxidation studies, reduction experiments, and catalyst development.

The rotating design enables continuous sample movement during thermal processing—essential for accurate material characterization and process development in batch operations requiring sample homogeneity.

Trusted by industry leaders worldwide

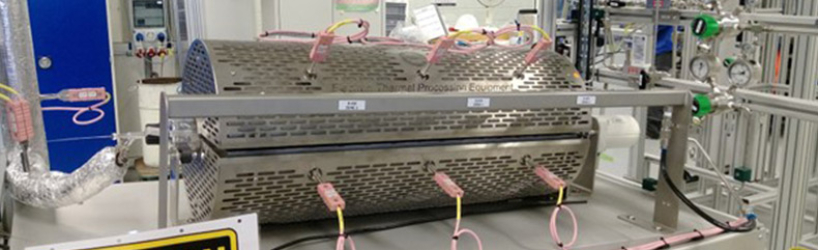

Case study: Advanced reactor processing solution

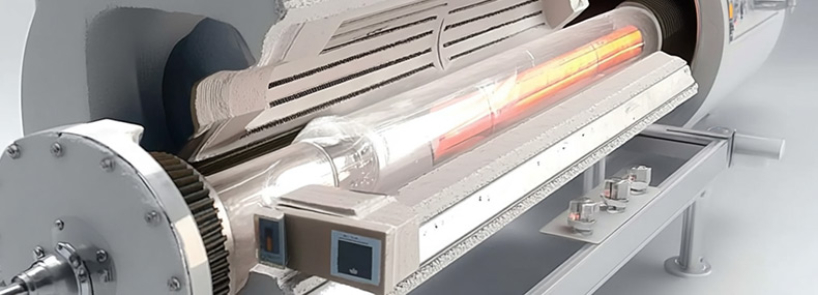

A petrochemical industry leader approached Electron with demanding requirements for experimental reactor processing requiring precise temperature control and rapid thermal cycling. The challenge involved processing materials in a 1-meter quartz glass reactor tube (50mm diameter) while maintaining uniform temperatures and achieving rapid cooling capabilities. The combination of fragile quartz construction, temperature limitations, and process accessibility requirements presented a complex engineering challenge.

Thermal solution

Electron delivered a custom rotary tube furnace system that achieved exceptional thermal performance within strict operational constraints:

- Operating range up to 850°C

- Three independent heating zones

- Rapid thermal cycling with forced convection cooling system

- Consistent thermal distribution across the entire reactor length

The system's exceptional performance in handling delicate reactor materials while maintaining precise thermal control led to continued collaboration on advanced process development projects, demonstrating the client's confidence in Electron's specialized engineering capabilities for complex reactor applications

Engineering features

The custom-engineered solution featured:

- Split design with automated opening mechanism for easy reactor access

- Fixed-speed rotation system optimized for process requirements

- Multiple cooling nozzles positioned for uniform heat removal and low noise operation

- Adjustable support frame enabling various furnace angles to influence material flow

- Specialized mounting system protecting delicate quartz reactor components

- Integrated safety systems preventing thermal damage to reactor materials

Custom rotary tube furnaces excel in applications requiring uniform material exposure to heat with continuous movement. They're extensively used in physicochemical processing, including sintering, pyrolysis, calcination, and coating applications.

The rotating design ensures consistent thermal treatment across every particle, eliminating hot spots while supporting controlled atmosphere conditions for processes requiring exact temperature profiles up to 1700°C.

Yes, Electron's rotary tube furnaces are engineered for continuous operation with precision-controlled rotation speeds.

For continuous processing, specialized material handling systems ensure consistent throughput while maintaining precise temperature control and atmospheric conditions.

These systems support industrial-scale production with minimal downtime and exceptional material uniformity, critical for coating applications and high-volume material transformation.

Electron provides multiple reactor material options optimized for specific temperature ranges and chemical environments: quartz glass (up to 1200°C), ceramic (up to 1800°C), and specialized metal alloys (up to 1400°C).

Ultra-high temperature applications to 1700°C utilize advanced ceramic compositions with exceptional thermal stability. Each material is selected based on process requirements, reactivity concerns, and temperature profile needs.

Electron's rotary tube furnaces are engineered around precise process demands rather than standardized specifications. Customization encompasses rotation speed control, reactor material selection, temperature zone configuration, gas flow management, and material handling systems.

Available in various diameters and lengths with specialized mounting options, these systems integrate seamlessly with existing processes while addressing unique operational challenges in research and production environments.

Selecting the appropriate rotary tube furnace requires systematic analysis of critical process parameters: maximum operating temperature, material characteristics, batch size or throughput requirements, and rotation dynamics.

Consider specific factors like gas atmosphere needs, chemical compatibility of reactor materials, and integration with upstream/downstream processes. Electron's thermal specialists evaluate these requirements, material transformation mechanics, and scaling considerations to design rotary systems that optimize both process performance and operational efficiency.

Premium rotary tube furnaces deliver exceptional temperature uniformity through the combination of precision heating elements and continuous material rotation. Typical systems achieve ±2-3°C uniformity at higher temperatures and ±5°C at lower ranges across the heated length.

This precision requires sophisticated multi-zone heating design, optimal rotation speed calibration, and advanced PID control algorithms—all standard features in Electron's custom rotary systems.

Electron's custom rotary tube furnaces deliver continuous rotation for uniform heating. Engineered for research, OEMs and industrial processing for reliable results.