Custom split tube furnaces: precision-engineered thermal solutions

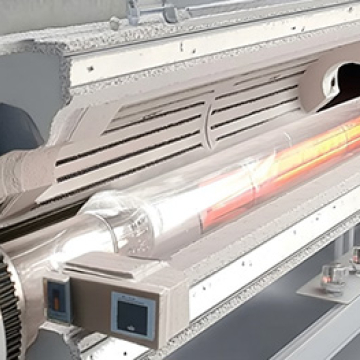

Electron develops high-performance split tube furnaces designed to meet the most demanding thermal process requirements. These custom-built systems feature multi-zone heating, exact temperature profiling, and flexible configurations tailored to the specific application. With reliable operation up to 1700°C and beyond, they provide uniform heating, process accuracy, and minimal maintenance.

From lab-scale research to industrial-scale production, Electron’s engineering team delivers fully customized furnace solutions that push the boundaries of temperature control and thermal efficiency.

Custom split tube furnaces for thermal processing

At Electron, every split tube furnace is engineered to meet a specific process challenge—whether for analytical labs or high-throughput production. Our process-first approach supports complex heating profiles, adaptable heater layouts, and custom mounting options for maximum compatibility.

These purpose-built systems ensure energy-efficient performance, consistent results, and long-term reliability, giving advanced manufacturers and research teams the precision and flexibility required to operate at the highest standards.

Why choose tailored split tube furnaces?

Standard furnaces with fixed designs can lead to process inefficiencies, maintenance delays, and compromised results. Custom split tube furnaces eliminate these limitations with their hinged, clamshell design that streamlines loading, maintenance, and modifications -ideal for dynamic setups and multi-step workflows. Delicate or sensitive materials benefit from stable, consistent profiles without exposure to thermal shock.

Combined with multi-zone temperature control, spring-loaded thermocouples, and robust stainless steel housings, these systems are available in horizontal or vertical formats and customizable with materials such as Aluminum, bronze, or brass.

Need help selecting the right split tube furnace?

Not sure which split tube furnace configuration matches specific process requirements? Electron's thermal engineers provide expert guidance for optimal system design and integration.

Key features

Each Electron split tube furnace is a tailor-made thermal system, designed around a specific process—not a catalogue of fixed specs.

- Flexible multi-zone temperature profiles REACH-compliant materials

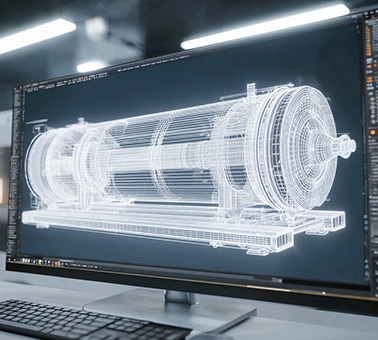

- Simulation-based thermal design for maximized performance and energy distribution

- Fully in-house design and production—from engineering to final assembly

- Guaranteed isothermal zone lengths

- Optional rotating furnace modules

- Durable materials such as quartz and ceramic for enhanced longevity

- Robust stainless steel casing for durability in harsh environments

- Built to operate up to 1700°C and beyond, depending on application needs

Customization for specialized applications

Electron's split tube furnaces adapt to the most challenging process requirements. From specialized manufacturing to advanced materials research, each system is designed around specific thermal profiles, space constraints, and integration needs.

Common customizations include specialized atmosphere control systems, additional temperature monitoring points, automation interfaces, and vacuum compatibility—all engineered to maintain optimal performance while addressing unique operational challenges.

Electron's engineering team provides comprehensive thermal process analysis, identifying critical parameters and designing custom furnace solutions that optimize both technical performance and operational efficiency for specialized applications.

High-temperature split tube furnaces for advanced applications

Electron delivers exceptional temperature control and rapid thermal cycling for research laboratories, manufacturers, and industrial production facilities. Each system offers unparalleled durability with flexible mounting options for specialized process integration.

Why choose Electron?

With a proven track record of delivering high-performance furnaces, Electron offers split tube furnace solutions tailored to the most demanding industrial and research applications. Our expertise in precision heating, advanced customization, and seamless integration ensures exceptional performance, reliability, and efficiency for every project.

In-depth process expertise and strategic partnership

Electron isn’t just a supplier, we are your strategic partner. Our in-house R&D facilities and process validation capabilities empower us to offer unique insights and solutions. We understand the challenges of scaling from laboratory setups to full-scale production, guiding you through every technical and strategic decision to optimize your process performance.

Fully customized solutions for specific processes

No two processes are identical. That’s why Electron specializes in fully tailored furnace solutions for diverse applications: from laboratory research and semiconductor processing to industrial-scale production. We design bespoke systems that integrate seamlessly into existing setup, ensuring that every configuration meets unique operational needs.

Expert support and guidance from concept to commissioning

Choosing Electron means gaining a dedicated team of engineers and thermal processing specialists who provide comprehensive support from initial consultation through installation, testing, and optimization. Our expertise ensures efficient scale-up, improved process control, and superior results, making our customers’ success our top priority.

Applications of custom split tube furnaces

Split tube furnaces from Electron support critical thermal processes across multiple industries, with custom configurations available for specialized applications.

Research & innovation

Custom high-temperature split tube furnaces from Electron empower universities and R&D centers to advance materials science, catalysis, and chemical process innovation.

Multi-zone heating and exceptional temperature uniformity enable accurate experimentation with carbon capture, ceramic sintering, oxidation behavior and diffusion heat treatment.

The hinged design ensures rapid sample access—critical for iterative research in high-tech environments.

Analytical integration

Leading analytical equipment manufacturers integrate Electron’s custom split tube furnaces for unmatched thermal control and durability.

These precision-engineered heating systems meet tight spatial requirements while delivering consistent temperature stability.

Ideal for gas analysis, spectrometry, and thermal testing, they minimize downtime and integrate seamlessly into OEM analytical instruments and lab automation platforms.

Thermal processing

Electron’s industrial-grade custom split tube furnaces provide scalable, high-performance thermal systems for continuous operation in production settings.

Designed for integration into automated manufacturing cells, they support powder processing, metal treatments, and oil cracking.

Rugged stainless steel construction, multi-zone control, and minimal maintenance deliver reliable uptime and energy-efficient process consistency.

Trusted by industry leaders worldwide

Case study: Precision under pressure

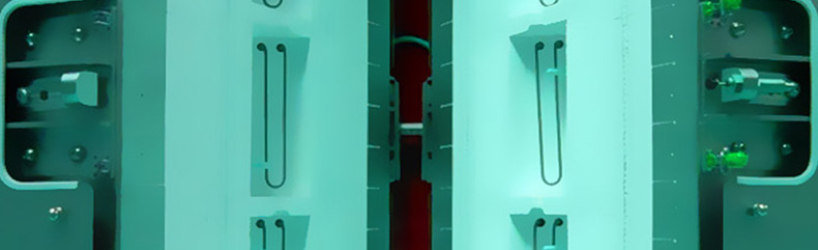

A petrochemical company approached Electron with a demanding research application requiring exceptional temperature uniformity across a wide operating range. The challenge was compounded by the need to easily exchange reactors of various materials and dimensions, with internal pressures reaching up to 400 bar. This combination of high-temperature precision and high-pressure containment presented a significant engineering challenge.

Thermal solution

Electron delivered a vertical split tube furnace that achieved remarkable temperature uniformity across an extensive operating range:

- 200-600°C: ±6°C uniformity

- 600-1000°C: ±4°C uniformity

- 1000-1500°C: ±2°C uniformity

The system's exceptional performance and reliability led to a follow-up order for an identical unit several years later, demonstrating the client's confidence in Electron's engineering capabilities and the system's value to their research operations.

Engineering features

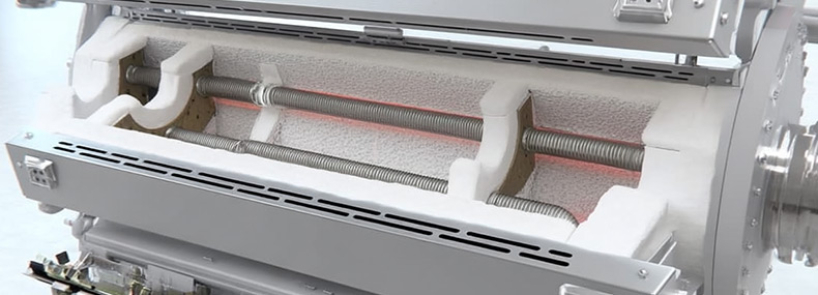

Our custom-engineered solution featured:

- Three Kanthal Super 1800 heating zones

- 13 strategically positioned thermocouples for precise control, monitoring, and safety

- Easy-open split design for rapid access

- Quick-connect system fabricated from high-performance Hastelloy alloy for reactor changes

- Active air cooling system to protect critical seals

- Ergonomic support frame for optimal operator access

The system's exceptional performance and reliability led to a follow-up order for an identical unit several years later, demonstrating the client's confidence in Electron's engineering capabilities and the system's value to their research operations.

Custom split tube furnaces excel in demanding applications requiring precise temperature control and easy chamber access. They're extensively used in material characterization, annealing, research, and specialized industrial heat treatments.

Their split design facilitates rapid sample changes and maintenance while maintaining thermal precision for critical processes like CVD, powder processing, and diffusion treatments at temperatures up to 1700°C.

Electron specializes in fully customized split tube furnaces engineered around specific process demands. Customization options include flexible zone configurations, adaptable heater alignments, specialized process tube materials, and tailored mounting solutions.

Available in horizontal or vertical orientations with various construction materials from stainless steel to specialty alloys, these systems integrate seamlessly with existing processes while addressing unique operational challenges.

Choosing the right split tube furnace requires evaluation of key process parameters: maximum operating temperature, required temperature uniformity, heating/cooling rates, and configuration (horizontal or vertical).

Consider specialized requirements like atmosphere control, sample dimensions, and integration with existing systems. Electron's thermal process specialists analyze these factors to develop custom furnace specifications optimized for specific applications, ensuring maximum performance and operational efficiency.

Yes, Electron's split tube furnaces feature sophisticated multi-zone heating systems with independent temperature control for each zone. This advanced capability enables precise thermal profiling across different sample areas, critical for applications like controlled diffusion, gradient sintering, and advanced materials research. Each independently regulated zone achieves exceptional uniformity (±2°C at higher temperatures), essential for processes where specific temperature profiles directly determine material properties.

Their split design facilitates rapid sample changes and maintenance while maintaining thermal precision for critical processes like CVD, powder processing, and diffusion treatments at temperatures up to 1700°C.

Electron's high-temperature split tube furnaces operate effectively up to 1700°C, with specialized designs available for ultra-high-temperature applications. The temperature capability depends on heating element selection, insulation materials, and process requirements.

Each system is engineered with premium Kanthal elements and optimized multi-zone configurations to deliver exceptional thermal stability and uniformity even at extreme temperatures.

Advanced custom split tube furnaces support controlled atmospheres and vacuum processing through specialized sealing mechanisms, gas-tight process tubes, and appropriate material selection.

These systems facilitate processes requiring inert gases (argon, nitrogen), reactive atmospheres (hydrogen, oxygen), or vacuum conditions while preserving the accessibility benefits of the split design. Custom gas flow management systems can be integrated for complex processes like oil cracking or chemical vapor deposition.

Electron's custom split tube furnaces deliver exceptional thermal uniformity. Engineered for research, OEMs and industrial processing for reliable results.