Custom laboratory tube furnaces: precision research solutions

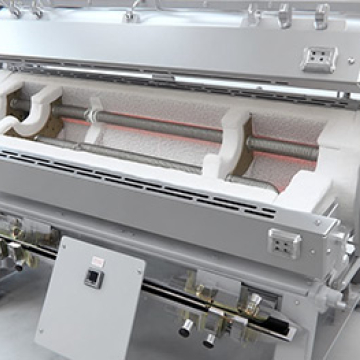

Electron develops high-performance laboratory furnaces designed to meet the most demanding research and analytical requirements. These custom-built systems feature multiple independent heating zones, precise temperature control, and flexible configurations tailored to specific laboratory applications. With reliable operation up to 1200°C and specialized designs extending beyond, they provide exceptional temperature uniformity, analytical accuracy, and user-friendly operation.

From materials research to analytical chemistry, Electron's engineering team delivers fully customized laboratory furnace solutions that advance research capabilities while maintaining the precision and reliability essential for scientific excellence.

Custom laboratory furnaces for research excellence

At Electron, every laboratory tube furnace is engineered to meet specific research challenges—whether for technical universities, R&D environments, or analytical testing facilities. Our process-first approach supports advanced temperature profiling capabilities, integrated data logging systems, and modular designs that adapt to changing research requirements.

These purpose-built systems ensure energy-efficient operation, reproducible results, and exceptional reliability, giving research teams and analysts the precision and consistency required to advance scientific discovery.

Why choose custom lab furnaces?

Standard laboratory furnaces often fail to meet precise temperature control and uniformity requirements essential for advanced research. Custom laboratory furnaces eliminate these limitations through application-specific work tube configurations and simulation-optimized heating element positioning. REACH-compliant materials ensure safety compliance and research integrity for heat treatment and specialized materials processing.

Combined with programmable temperature controllers, specialized atmosphere capabilities, and ergonomic loading systems, these furnaces accommodate various tube diameters and heated lengths. Custom configurations support specialized sample holders, gas flow requirements, and analytical instrumentation integration for comprehensive research capabilities.

Need help selecting the right laboratory tube furnace?

Not sure which lab furnace configuration matches specific research requirements? Electron's thermal engineers provide expert guidance for optimal system design and analytical integration.

Key features

Advanced thermal technology engineered for precision in demanding research and analytical applications:

- Precision temperature profiling

- REACH-compliant materials

- Compact designs optimized for laboratory space constraints

- Fully in-house design and manufacturing

- Guaranteed isothermal zone lengths

- Modular configurations for evolving research requirements

- Specialized work tube options in quartz, ceramic, or metal configurations

- Integrated data logging capabilities for research documentation and validation

- Ergonomic sample loading systems for safe and efficient operation

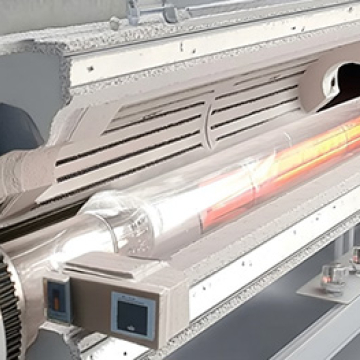

- Operating temperatures up to 1700°C with specialized designs extending beyond

Customization for laboratory applications

Electron's laboratory tube furnaces adapt to the most demanding research requirements. From university laboratories to industrial R&D facilities, each system is designed around specific analytical protocols, sample types, and integration needs.

Common customizations include specialized atmosphere control systems, automated sample handling, temperature monitoring for validation, and integration with analytical instrumentation—all engineered to maintain research-grade performance while addressing unique laboratory challenges.

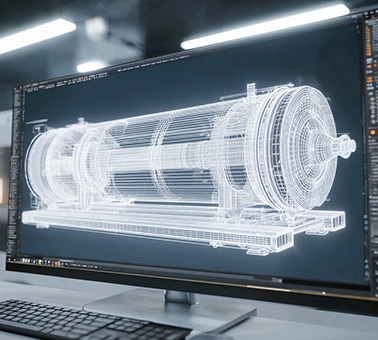

Electron's engineering team provides comprehensive research application analysis, identifying critical parameters and designing custom laboratory furnace solutions that optimize both analytical performance and operational efficiency for specialized research applications.

High-performance lab furnaces for advanced applications

Electron delivers exceptional uniformity and continuous material processing for research laboratories, materials developers, and industrial manufacturing operations. Each system offers unparalleled durability with adaptable configurations for specialized thermal processes up to 1700°C.

Why choose Electron?

With a proven track record of delivering high-performance furnaces, Electron offers lab tube furnace solutions tailored to the most demanding material processing applications. Our expertise in precision heating, advanced customization, and seamless integration ensures exceptional performance, reliability, and efficiency for every project.

In-depth process expertise and strategic partnership

Electron isn’t just a supplier, we are your strategic partner. Our in-house R&D facilities and process validation capabilities empower us to offer unique insights and solutions. We understand the challenges of scaling from laboratory setups to full-scale production, guiding you through every technical and strategic decision to optimize your process performance.

Custom-designed systems for precision and efficiency

No two processes are identical. That’s why Electron specializes in fully tailored laboratory furnace solutions for diverse applications: from material science to process development to quality control and testing. We design bespoke systems that integrate seamlessly into existing setup, ensuring that every configuration meets unique operational needs.

Expert support and guidance throughout the process

Choosing Electron means gaining a dedicated team of engineers and thermal processing specialists who provide comprehensive support from initial consultation through installation, testing, and optimization. Our expertise ensures efficient scale-up, improved process control, and superior results, making our customers’ success our top priority.

Applications of custom laboratory furnaces

Laboratory furnaces from Electron support critical thermal processes across research institutions and industrial R&D facilities, with custom configurations available for specialized analytical applications.

Materials science & characterization

Research laboratories rely on Electron's laboratory tube furnaces for precise materials analysis and development. These systems deliver exceptional temperature control essential for heat treatment studies, phase transformation analysis, and thermal property characterization.

Custom work tube configurations accommodate various sample geometries while maintaining optimal temperature distribution around specimens.

Advanced heating element positioning ensures uniform thermal exposure critical for reproducible materials research and accurate thermal analysis data.

Process development & scale-up

Industrial R&D laboratories leverage Electron's systems for process development and pilot-scale testing.

These furnaces enable researchers to optimize thermal processes before scale-up, validating temperature profiles and reaction conditions.

Custom configurations support process parameter studies while data logging capabilities provide comprehensive documentation for technology transfer and production implementation.

Quality control & testing

Quality control laboratories utilize Electron's systems for standardized testing protocols and material validation.

Our furnaces support routine thermal testing, compliance verification, and failure analysis with exceptional repeatability.

Custom configurations accommodate standard test specimens while programmable controllers ensure consistent thermal cycles required for certification testing and quality assurance procedures.

Need help selecting the right laboratory tube furnace?

Not sure which lab furnace configuration matches specific research requirements? Electron's thermal engineers provide expert guidance for optimal system design and analytical integration.

Customized lab tube furnaces excel in applications demanding precise temperature control and small sample volumes. They're essential for materials characterization, thermal analysis, catalyst research, and fuel cell testing.

The controlled atmosphere capabilities support oxidation studies, reduction experiments, and chemical synthesis. High heating rates and excellent temperature uniformity make them ideal for sintering, calcination, and phase transformation studies in research environments.

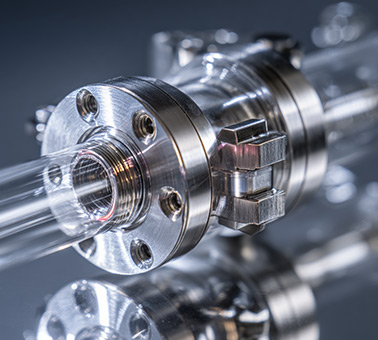

Custom laboratory tube furnaces are engineered around specific research requirements rather than generic specifications. They feature application-specific heating zones, tailored atmosphere control systems, and specialized sample handling configurations. Temperature profiles, heating rates, and uniformity specifications are optimized for particular processes.

Integration with analytical instrumentation, automated sample handling, and specialized data logging capabilities address unique research protocols that standard tube furnaces cannot accommodate effectively.

Electron’s lab tube furnaces achieve superior temperature uniformity through application-specific heating element design and thermal modelling. Uniformity specifications are tailored to research requirements, achieving ±0.5-1°C in critical zones.

Multi-zone heating systems enable precise thermal gradients or exceptional uniformity as needed. Custom insulation materials and heating element positioning optimize thermal performance for specific sample types and experimental conditions, ensuring reproducible results.

Customized laboratory tube furnaces support specialized atmosphere requirements including multi-gas mixing systems, precise flow control, and contamination-free environments. Tailored gas delivery systems accommodate reactive or corrosive atmospheres -including hydrogen, HF, and HCl commonly used in research applications- while maintaining system integrity. Custom sealing mechanisms and specialized work tube materials ensure atmospheric purity.

Advanced monitoring and control systems enable real-time atmosphere composition adjustment during experiments, supporting complex research protocols requiring dynamic environmental conditions.

Tailored laboratory furnace design begins with comprehensive application analysis to identify critical process parameters. Our engineering team evaluates sample characteristics, thermal requirements, atmosphere needs, and integration requirements.

Custom heating zone configurations, specialized work tube materials, and tailored control systems are selected based on specific research objectives. Thermal modelling and prototype testing validate performance before final system delivery, ensuring optimal results for unique applications.

Electron’s custom laboratory tube furnaces include validation documentation tailored to specific research requirements. Temperature mapping, uniformity surveys, and atmosphere verification testing ensure system performance meets specifications. Customized calibration protocols and ongoing support maintain system accuracy over time.

Performance qualification documentation supports regulatory compliance and research validation requirements. Dedicated technical support provides ongoing guidance for method development and process optimization throughout the system lifecycle.

Electron's custom lab tube furnaces deliver research-grade precision with tailored configurations, advanced control, and specialized atmospheres.